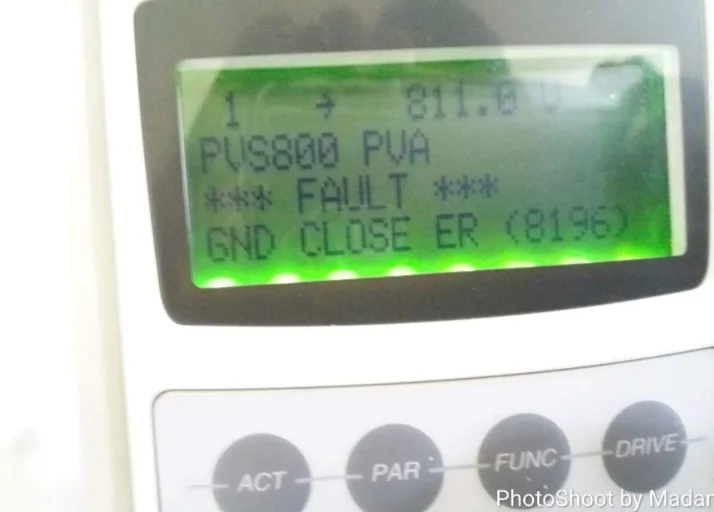

In utility-scale solar plants, ground faults are commonly treated as protection events rather than early indicators of solar energy yield loss. When insulation resistance drops below the configured threshold, the inverter trips, and corrective maintenance begins. However, in operating utility-scale solar plants, performance degradation often begins long before inverter protection activates.

By the time an inverter registers a ground fault trip, the plant may already have suffered measurable energy loss, reduced Capacity Utilization Factor (CUF), and declining Performance Ratio (PR).

Understanding this early degradation phase is critical for serious solar asset management and long-term reliability optimization.

What Is a Ground Fault in a Solar PV System?

A ground fault occurs when a current-carrying DC conductor unintentionally makes contact with earth or a grounded metallic structure. Instead of flowing entirely through the intended electrical path, part of the current leaks to ground. This leakage current increases system losses, alters voltage balance, and introduces electrical stress within the inverter and connected equipment.

In modern high-voltage PV systems operating at 1000V or 1500V DC, even minor insulation degradation can create measurable leakage paths that impact plant performance before triggering inverter protection.

How Ground Faults Reduce Solar Plant Performance Before Tripping

1. Continuous Leakage Current Causes Energy Loss

Low-level insulation breakdown allows small but continuous leakage currents to flow toward ground. Although these currents may remain below inverter ground-fault trip thresholds, they still represent real electrical losses. Over time, this reduces inverter loading efficiency and lowers total exported energy.

At scale, even minor underperformance across multiple strings contributes to reduced daily yield and measurable CUF degradation.

2. Voltage Shift Away from Maximum Power Point (Vmp)

When leakage current increases significantly, small voltage drops can develop across affected string conductors. Although these drops are usually minor, they can shift the operating point slightly away from the true Maximum Power Point (Vmp). In certain inverter topologies, asymmetrical leakage can slightly influence internal reference stability and marginally affect MPPT tracking accuracy.

Although this effect is typically small, even minor deviations sustained over long operating hours can contribute to measurable energy yield loss in large utility-scale solar plants.

For example, in a 10 MW utility-scale solar plant, even a 0.5% unexplained PR drop caused by undetected leakage can translate into significant annual energy yield loss. Because these reductions accumulate gradually, they are often misinterpreted as seasonal variation rather than electrical degradation.

3. Increased EMI Circulating Currents and Internal Heating

Modern solar inverters rely on high-frequency switching, which inherently generates electromagnetic interference (EMI). Under normal conditions, internal filters and grounding systems manage these currents effectively. However, when unintended ground paths exist, they create additional routes for high-frequency circulating currents.

The result is increased internal losses and additional heat within filters, semiconductor devices, cables, and terminals. This extra heat does not contribute to exported power and instead accelerates component aging.

Ground Faults and Potential Induced Degradation (PID)

Ground path irregularities and sustained leakage conditions are not the direct cause of Potential Induced Degradation (PID), but they often coexist in high-voltage, high-humidity environments. PID develops under prolonged electrical bias stress combined with temperature and moisture exposure.

Abnormal leakage behavior may therefore serve as an early indicator of insulation stress or module-level degradation that warrants deeper investigation, especially in utility-scale solar plants operating at elevated DC voltages.

When insulation resistance weakens, leakage currents increase electrical stress across module cells. Over extended operation, this stress contributes to irreversible power loss at the module level.

Important: Effective insulation resistance monitoring and early PV ground fault analysis help detect conditions that may accelerate long-term module performance loss.

Humidity Cycles and Intermittent Ground Faults

Morning dew, seasonal humidity, and condensation frequently create temporary leakage paths within connectors, junction boxes, or damaged cable insulation. These intermittent ground faults are particularly challenging because they often appear at sunrise and disappear as temperatures rise.

By midday, the fault condition may no longer be detectable during manual inspection. Without high-resolution performance analytics, these patterns remain invisible while CUF and PR continue to deteriorate.

Why Data-Driven Solar Analytics Matters

Traditional SCADA systems focus primarily on inverter status and availability. However, subtle PR degradation, CUF shifts, and inverter efficiency reduction require deeper performance analytics. Detecting solar inverter leakage current trends, unexplained temperature rise, and gradual performance deviation enables corrective action before major failures occur.

Ground faults are not only safety concerns. They are performance and reliability issues that reduce solar plant efficiency before protection mechanisms activate.

Early anomaly detection significantly reduces unaccounted energy loss and improves long-term plant reliability.

Detecting Ground Fault Impact Through Performance Analytics

Advanced solar plant performance monitoring platforms analyze inverter efficiency trends, CUF deviation patterns, and multiple Performance Ratio (PR) metrics to detect hidden ground fault behavior before inverter trips occur.

Solar Performance Analysis Tools

CUF Calculator

Calculate Capacity Utilization Factor and identify yield deviations

Efficiency-Based PR Calculator

Analyze performance ratio with inverter efficiency metrics

Temperature-Corrected PR Calculator

Normalize PR for temperature effects and isolate losses

Instantaneous PR Calculator

Real-time performance ratio monitoring and analysis

Specific Yield Calculator

Measure kWh/kWp output and benchmark plant performance

These tools help operators quantify solar energy yield loss, isolate inverter-level efficiency reduction, and distinguish insulation-related degradation from environmental variation.

Conclusion: Ground Faults Are Performance Issues Before They Are Protection Events

Ground faults should not be viewed solely as safety incidents. They are early-stage performance degradation mechanisms that reduce exported energy, lower CUF, decrease PR, and accelerate equipment aging. Waiting for inverter trips as the primary detection method guarantees avoidable production losses.

Solar plants that maintain consistently high performance metrics are those that rely on advanced solar performance monitoring and analytics rather than reactive maintenance strategies.

Even a sustained 0.3–0.5% annual energy yield reduction in a 50 MW utility-scale solar plant represents significant revenue impact over the asset lifetime. Because ground faults often develop gradually and remain below protection thresholds, performance analytics becomes a financial risk management tool rather than only a maintenance function.

Key Takeaway

In modern high-voltage PV systems, early detection of leakage current is no longer optional. It is a fundamental requirement for maximizing long-term solar plant performance and protecting asset value.